Retail supply chains are becoming increasingly complex due to rising customer expectations, demand fluctuations and the challenges of omnichannel fulfillment. The days of steady demand and linear supply chains are gone, and retailers need to consider how goods move from suppliers to shoppers.

Optimising supply chains is essential. To remain competitive, retailers need to constantly review and refine their networks to ensure they’re fast, reliable and cost-effective. But how, and when, should you optimise your supply chain? A retail supply chain with the right balance of cost and service level is key for retailers looking to gain a competitive advantage in an omnichannel retail world.

A strategic network evaluation provides a comprehensive view of your business, helping you uncover and leverage new opportunities for growth and optimisation. A successful supply chain network design can give retailers a competitive advantage, pinpoint ways to reduce costs, improve service levels, shorten overall cycle times, streamline all processes and systems and much more. If you haven’t looked at your network strategy lately, you’re likely either sacrificing service to customers or spending too much money.

Before we can optimise the supply chain, we must first explore what the supply chain looks like and what network optimisation entails.

What is Retail Supply Chain?

A retail supply chain covers a product’s journey from raw material sourcing through to delivery to the customer. It’s a complex chain that includes suppliers, manufacturers, warehouses, distribution centres, logistics providers and retail stores or ecommerce platforms.

Retail supply chains must manage high SKU counts, frequent product changes and fluctuating demand caused by special offers and/or volatile consumer trends. Retailers need to balance efficiency with flexibility, ensuring inventory is available wherever customers choose to shop.

Modern supply chains also require end-to-end visibility. Cloud-based ERP systems, AI-driven forecasting and real-time inventory tracking can support proactive decision-making and enable companies to respond more quickly to changing conditions, reducing costs and minimising waste.

What is Supply Chain Network Optimisation?

Supply chain network optimisation is the process of designing a supply chain network that properly balances cost, performance and service. It aims to ensure a good customer experience while minimising company costs through efficient transportation routes, good warehouse locations and effective distribution strategies.

Building a data-driven network helps companies ensure their inventory is in the right place at the right time, whether that’s distribution centres (DCs), warehouses, third-party logistic providers (3PLs), dropship vendors or stores.

Modelling and simulation enable organisations to perform well today and add distribution centres, shift fulfilment strategies and change routes as required to maintain or improve service quality.

Benefits of Supply Chain Network Optimisation for Retail

Optimising your supply chain network delivers measurable improvements across key business drivers:

- Reduced fulfilment times: Lower fulfilment times allow you to meet customer demands reliably, ensuring better on-shelf availability and reducing delivery times.

- Reduced costs: Smarter network design helps reduce costs associated with transportation, warehousing and material handling inefficiencies, maximising the profit potential of your supply chain network.

- Improved customer satisfaction: Reliable supply chains reduce delays, lost packages and order errors.

- Improved agility: An agile supply chain can respond confidently to seasonal spikes, global disruptions and changing market conditions.

- Improved sustainability: Improvements like optimised shipping routes can reduce your organisation’s carbon footprint.

- Improved inventory visibility and allocation: A supply chain network optimisation gives you a holistic view of inventory flow across your entire network and ensures its flowing through the correct nodes.

6 Scenarios Where Retailers Should Consider Optimising Their Supply Chain

Retailers rarely think about supply chain optimisation until they notice issues with their existing systems. Early action can save you a lot of time and stress.

If your organisation recently underwent one of the following six changes, it’s time to reexamine your supply chain network.

1. You Recently Implemented a Ship-From-Store Strategy

Many retailers are now using stores as fulfilment centres to enable ship-from-store strategies. This gives them a competitive edge and allows customers to save time and money. Ship-from-store can improve customer satisfaction, but it also increases supply chain complexity.

Maintaining accurate inventories and managing the last-mile can be challenging. An optimised supply chain network helps you identify the best store for order fulfilment and ensures high service levels across all your channels. When properly optimised, ship-from-store makes your stores an asset rather than adding more liabilities to your supply chain.

2. Your Company Merged with Another Retailer or Acquired Another Brand

Mergers and acquisitions often lead to duplicated networks, redundant systems and inefficiencies. Facilities overlap, carrier contracts multiply and supply chain visibility decreases.

Post-merger network optimisation helps you leverage the best parts of each area of the business. You can save money, expand your customer reach and ensure smooth integration between brands, whether they continue to operate independently or become a single company.

3. You Experienced a Recent Geographic Expansion

Expanding into new markets often reveals the limits of an existing supply chain. Longer delivery routes, inconsistent shipping times and rising logistics costs signal the need for a new approach. While it’s not unusual to expand slowly with limited offerings when entering a new market, over time, it’s vital to deliver a consistent level of service in all markets.

Network optimisation helps retailers identify optimal distribution centre locations, transportation routes and service zones. With the right network design, you can scale efficiently while maintaining consistent customer experiences in every market.

4. You’re Using a “Store Within a Store” Strategy

The “store within a store” model involves a large retailer playing host to a smaller one (perhaps in the form of a concession or pop-up shop). This model introduces new layers of operational complexity. Multiple inventory systems, brand owners and delivery requirements coexist under one roof. The complexity can cause confusion, errors and wasted effort in the supply chain.

Through supply chain network optimisation, retailers can synchronise these operations, define shared logistics workflows and align delivery schedules. When well-optimised, this model delivers seamless customer experiences and improved profitability across all in-store partnerships.

5. You Need to Reassess Your Inventory Flow Path

When certain stores experience frequent stockouts and others carry excess inventory, your inventory flow path may be misaligned.

Supply chain network optimisation helps you analyse the product journey in greater depth so you can send products to the right place the first time. Having a clear overview of consumer purchasing behaviours and product flows helps save time, reduce transfers and improve the customer experience.

You’ll also want to reassess your network strategy if your assortment or outbound order profiles change. This will ensure there is no wasted time or resources throughout the process. Even small changes in order profiles (including returns) can significantly affect your network.

6. It’s Been Five Years or More Since Your Last Network Strategy Was Implemented

Changing consumer expectations, evolving technologies and rising transportation costs mean it’s vital to review your supply chain network every few years. If it’s been five or more years since you evaluated your systems, you may find that you need to make efficiency improvements or changes that may result in significant cost savings.

Regular optimisation ensures your business remains agile, resilient and positioned for long-term success. Even if your organisation hasn’t expanded or made significant commercial changes, reevaluating customer preferences and changing product lines can make a supply chain review worthwhile.

A Supply Chain Network Before and After Optimisation

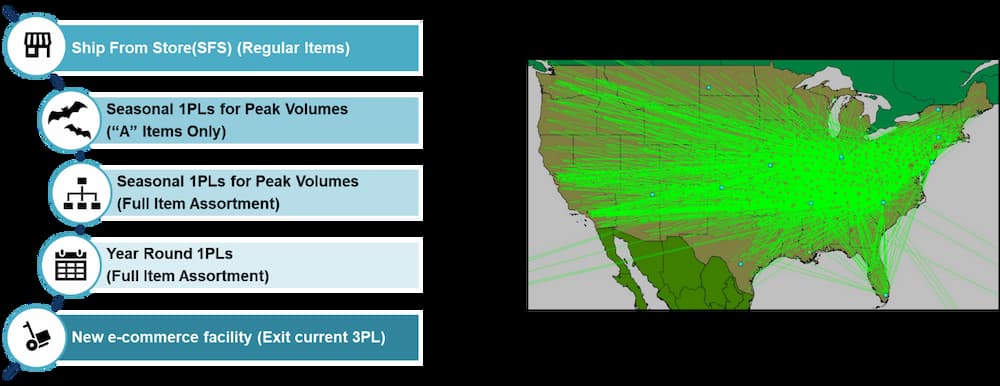

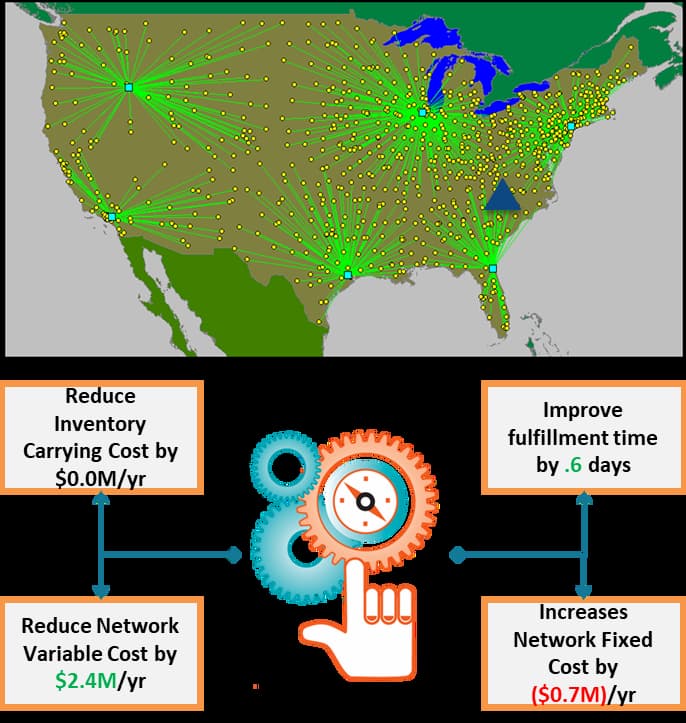

enVista has worked with many leading retailers, manufacturers and distributors to design an optimal supply chain network.

As these images show, before optimisation, many retail networks suffer from inefficiencies such as redundant facilities, long transit times and fragmented data. After optimisation, networks should be leaner, more synchronised and more customer-focused. e, see the before and after images below from a supply chain network analysis project.

Be Informed and Be Prepared

Retailers that thrive today continually reassess and refine their supply chain networks. Optimisation isn’t a one-time project — it’s a philosophy of continuous improvement.

Whether you’re expanding into a new market, integrating a new brand or scaling your business, supply chain network optimisation is crucial. Even relatively stable companies can benefit from a supply chain network optimisation to maintain their competitive advantage. Partner with enVista to uncover hidden opportunities, reduce costs and build a supply chain that’s ready for what’s next.

Contact us to learn more about enVista’s supply chain network optimisation services and schedule your assessment today.