Having the right warehouse technology is crucial for optimising supply chain operations. Too little technology can lead to inefficiencies and lack of visibility, while too much complexity can create silos, integration challenges and technical debt. To keep operations efficient and scalable, especially for companies undergoing mergers and acquisitions, simplifying operational complexity is essential.

Supply chain leaders looking to optimise warehouse processes must understand the key differences between warehouse management, control and execution systems.

Defining Warehouse Technology

There are three core systems that enable efficient warehouse operations: warehouse management systems (WMS), warehouse control systems (WCS) and warehouse execution systems (WES). Each system plays a distinct role in managing inventory, labour and automation, yet their functions often overlap. Choosing the right system requires a clear understanding of how inventory moves through the facility and how each system interacts with automation.

Warehouse Management System

A warehouse management system is a highly specialised supply chain business application that manages the flow of inventory into, within and out of a company’s distribution center (DC). Unlike WES and WCS, a WMS focuses on inventory visibility and operational task execution across multiple locations.

Key WMS Functions:

- Manages inventory within the four walls of the DC and across multiple locations

- Provides enterprise-wide inventory visibility

- Tracks orders and inventory at all times

- Controls labour tasks, including receiving, putaway, replenishment, cycle counting, picking and shipping

- Supports exception handling, including returns and quality assurance

Real-Time Capabilities in a WMS:

Most modern WMS solutions support:

- Wireless data terminals (RF devices) for real-time inventory tracking

- Bar-coded labels and RFID tags for enhanced accuracy

- Voice-enabled RF devices to improve picking efficiency

- Material handling equipment (MHE) messaging to facilitate automation but not direct control

While a WMS is essential for inventory management, it does not control machine-level automation such as conveyor sortation, carton tracking or machine signals. This is where a warehouse control system comes in.

Are you Ready for a Warehouse Management System?

Discover what every operations executive should know about selecting a WMS to ensure a positive ROI, and improved operations.

Warehouse Control System

A warehouse control system is a real-time automation control solution designed to manage the movement of cartons, pallets and items as they travel through automated MHE such as conveyors, sorters and AS/RS. It enables real-time communication and command processing between software and industrial hardware.

Key WCS Functions:

- In-line scale and print-and-apply label management

- Real-time control of material handling equipment (conveyors, sorters, AS/RS, pick-to-light, etc.)

- Equipment-level communications with PLCs (Programmable Logic Controllers)

- Automated sortation and picking processes

- Mobile and fixed scanner integration

What a WCS Does Not Do:

- Does not manage inventory at the enterprise level

- Does not interface directly with an ERP (typically)

- Does not handle labour management or transportation execution

- Does not allocate inventory within the warehouse

A WCS is ideal for highly automated environments that require real-time equipment control. However, if you need a solution that balances automation with broader inventory management, a warehouse execution system may be the right fit.

Warehouse Execution System

A warehouse execution system is a hybrid solution that combines elements of both WMS and WCS to optimise and balance warehouse workflows. It is often built by enhancing a WCS with WMS-like capabilities, or by developing a standalone WES with integrated automation control.

Key WES Functions:

- Provides visibility into automation performance while integrating with higher-level WMS functions

- Dynamically allocates and balances work across automated and manual processes

- Orchestrates order fulfilment workflows to optimise efficiency

- Supports wave management, light task management and single-channel inventory control

- Manages picking and shipping processes for fulfilment operations

What a WES Does Not Do:

- Does not manage all inventory locations within a DC (only those relevant to execution)

- Does not provide full transportation planning and shipping execution

- Does not support extensive cycle counting or physical inventory processes

A WES is most valuable in automated or semi-automated facilities where balancing work across automation and labour is critical. However, it lacks the complete inventory visibility and enterprise connectivity of a WMS.

Selecting the Best System for Your Business

Each warehouse technology serves a distinct purpose. Selecting the right system depends on your operational needs:

- Choose a WES if you need to optimise order fulfilment and balance work across manual and automated processes.

- Choose a WMS if you need comprehensive inventory management order tracking and enterprise-wide visibility.

- Choose a WCS if your warehouse is highly automated and requires real-time control over conveyors, sorters and AS/RS.

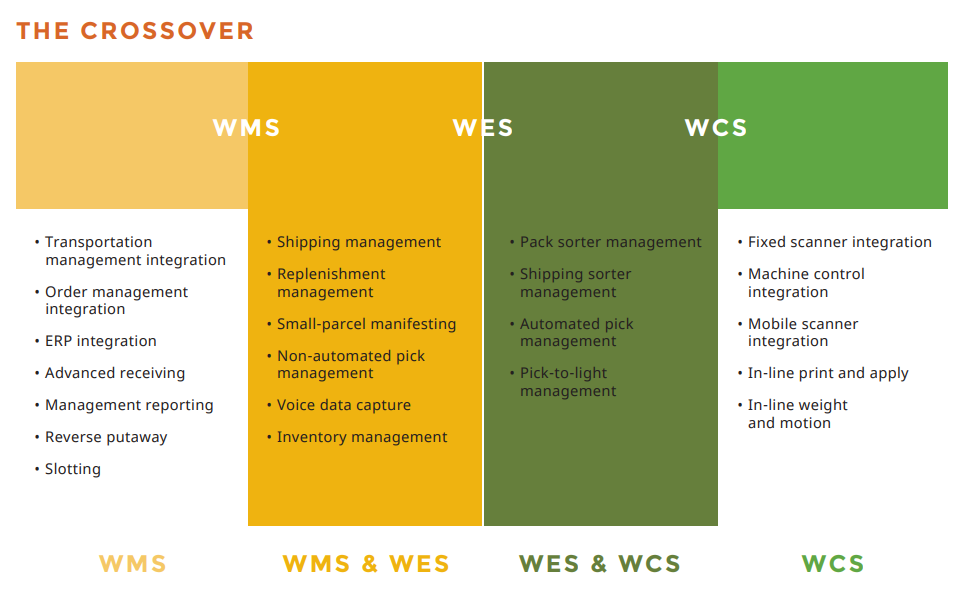

This chart provides a quick reference that can help you narrow down the correct solution for your company:

With increasing warehouse complexity and automation, the lines between WMS, WCS and WES are becoming blurred. Often, the answer isn’t only one of the three solutions, but a customised combination that tailors itself very specifically to the operations of the facility at hand. The right solution depends on how inventory moves through your facility, your level of automation and your strategic priorities.

To find out more about how a WMS, WCS or WES can impact your business and what questions you need to ask when deciding which system you should choose to implement, check out our WMS vs WCS vs WES white paper.

At enVista, we specialise in warehouse technology consulting, from system selection to implementation. If you want one-on-one time with a warehouse technology expert, we’d love to talk with you.