SALES & OPERATIONS PLANNING CONSULTING

Sales and operations planning services that drive profitability.

Today’s consumer expects a wide assortment of high-quality products delivered quickly and inexpensively. Through improved inventory management and more accurate demand forecasting, you can align demand with supply and drive toward an integrated business plan (IBP).

Benefits of Sales and Operations Planning

Sales and operations planning (S&OP) is a part of supply chain planning where a business achieves long-term synchronization across every stage of the supply chain. It utilizes data from all of a company’s key functional areas, including manufacturing, marketing, sales, distribution and operations and finance to achieve efficiency and cost savings.

S&OP helps align business objectives across departments, ensuring manufacturers’ supply can meet consumers’ demands. By taking a holistic approach, sales and operations planning helps organizations achieve synchronicity between departments, fulfill orders more quickly and improve customer satisfaction.

enVista helps customers bridge the gap between the traditional approach of doing manufacturing planning or sales forecasting as an exercise compared to driving alignment between the sales team, marketing, purchasing, lean manufacturing and logistics to ensure all functions are working under the same expectations towards the same goal.

Increased Customer Satisfaction

Our S&OP consultants help you identify and communicate key metrics and objectives across all functional teams in your organization as part of the sales and operation planning process. With these metrics and KPIs in mind, you can identify areas for improvement that will elevate customer satisfaction.

Optimized Production and Inventory Management

Our SKU-based analysis and "plan for every part" approach reduces wasted space, increases stock turnover and helps you better meet variable demand. We will help your organization decrease capital tied up in unsold inventory and increase inventory turnover.

Synchronization Between Departments

S&OP facilitates information sharing and aligns objectives across teams. For example, if the supply team is aware of the inventory team’s goal of reducing stock levels, they will know not to continue adding more inventory.

Correct Resources

Successful S&OP requires teams to work collaboratively. We enable your associates to become detail-oriented and think big-picture to drive actions through influencing.

Improved Demand Forecasting

Collecting historical data from sales, marketing, inventory and other teams and combining it with market research can help with demand forecasting. Using sophisticated statistical techniques, it's possible to anticipate fluctuations in demand so you can make better use of your storage space and stock budget.

AI and IoT Capabilities of S&OP Software

AI tools for analytics and IoT systems for inventory tracking augment the functionality of sales and operations planning software, empowering you to make faster and more accurate decisions. IoT tools can track deliveries in real-time, while AI can process huge volumes of information.

Get a Jumpstart on the Sales & Operations Planning Process

If you work with enVista for your sales and operations planning, we’ll follow an exhaustive process to craft a system that works for your organization:

- Data gathering: We start by collecting information on past trends and sales.

- Demand planning: We’ll review forecasts, taking potential variability into consideration, and evaluate customer service policies and promotional plans to conduct careful demand planning.

- Supply planning: During this stage, we’ll evaluate your organization’s ability to meet current and future demand.

- Plan reconciliation: We’ll measure your supply and demand plans against financial considerations.

- Finalize and implement: After reviewing and finalizing the plan, we’ll work closely with key stakeholders to ensure a smooth and seamless implementation.

Planning as a Service

enVista’s S&OP planning consultants will leverage their deep knowledge and experience in sales and operations planning to help you improve your strategic planning and decision-making our. Our consultants have extensive experience in a range of industries, understand industry best practices and excel at tailoring planning solutions to meet the unique needs and goals of each client. We’ll synchronize supply with demand to meet service and profitability expectations while elevating customer service and holding suppliers accountable.

With the support of our planning experts and advanced analytical tools, businesses can streamline their operations, optimize processes, and enhance accuracy in areas such as demand forecasting, inventory management and resource allocation.

Data-Driven Decision Making

Through deep analytics, we can help you identify trends and performance issues, forecast demand and set future fill rate expectations and labor requirements.

Accountability in Every Step

Our consultants will conduct operational assessments to help your organization identify key performance metrics, create policy documents to guide the process and develop a complete RACI chart.

Unmatched Success

enVista has helped many organizations achieve significant gains in efficiency and customer satisfaction. Our consultants worked with a leading sock and legwear designer and manufacturer to improve its S&OP strategy. By developing a multi-node inventory strategy model, the company benefited from inventory reductions of up to 10 percent and a 33 percent reduction in lost sales.

Featured Insights

White Paper

What Every Chief Supply Chain Officer Should Know about Supply Chain Responsiveness

Future-proof your supply chain with an adaptable response plan. Learn how to keep your supply chain responsive to change and disruption.

Blog

How to Select the Right Supply Chain Supply Chain Planning Software

Selecting the right supply chain planning software can transform your business operations, streamline processes and enhance efficiency. Here are the top five key considerations to help you make an informed decision.

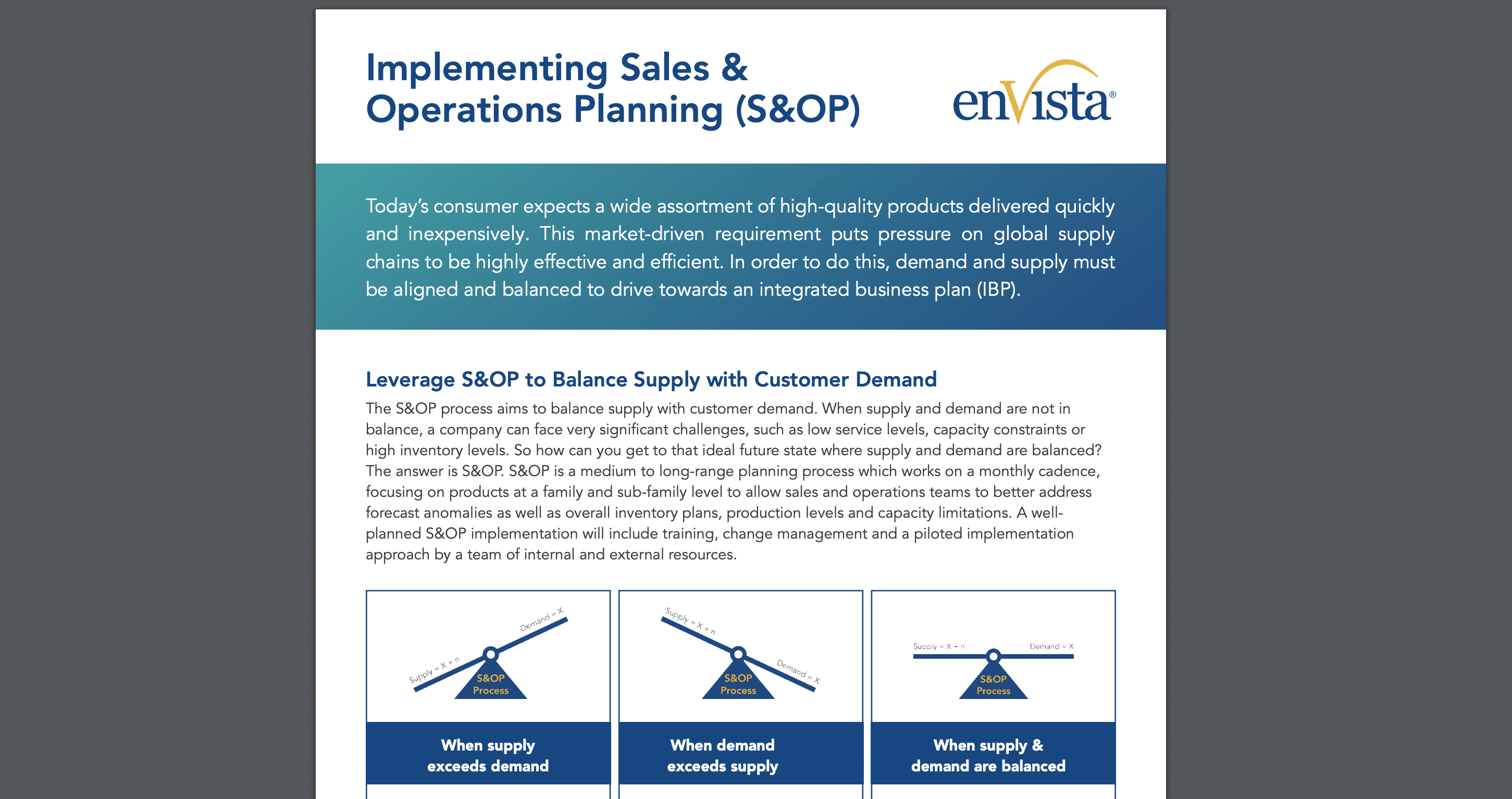

Data Sheet

S&OP

enVista can help you leverage S&OP to balance supply with customer demand. Contact us today to discuss your company’s needs.

Blog

10 Steps To Take To Be Ready For AI in Retail

explore 10 critical steps for retailers to take to prepare for implementing AI into their organization and processes and how the right consulting partner can help you achieve those steps.

Sales and Operations Planning Consulting FAQs

Sales and operations planning (S&OP) is a part of supply chain planning where a business achieves long-term synchronization across every stage of the supply chain. It utilizes data from all of a company’s key functional areas, including manufacturing, marketing, sales, distribution and operations and finance. The two goals of sales and operations planning consulting are to align business objectives across departments and to match consumer demand with supply from manufacturers. This is accomplished through careful project management and execution across business departments to provide a holistic approach to supply chain planning and operations.

S&OP’s virtue lies largely in its holistic approach. The overarching view helps organize business operations across the board, affecting almost every piece of an organization. For example, synchronization between departments can reduce the time needed to fulfill an order, allowing it to arrive faster and improve overall customer satisfaction. Cutting inventory costs by gaining a better view of supply and demand similarly can cut costs overall, helping a business become more profitable and efficient. In addition to increasing sales, some of the most common benefits of sales and operations planning include:

- Easier to understand and present data to share with stakeholders

- Improved levels of customer service

- Better product revenues

- Increased profitability

- Reduced lead times

- Lowered inventory

- Faster responsiveness

- Top-down control from management

- Better demand and supply forecast accuracy

The S&OP process can vary from organization to organization, as each company’s departments and goals will be slightly different. However, there are a few common steps that most planners tend to implement, as presented by Thomas Wallace and Robert Stahl.

- Data gathering: Information is collected on past sales and trends and used to create forecasts.

- Demand planning: This step includes checking forecasts, accounting for possible variability, revising customer services policy, tracking sources of demand, and creating promotion plans.

- Supply planning: The company’s ability to meet current and future demand is assessed. This is done by reviewing available inventory and capacity and then scheduling future operations.

- Plan reconciliation: Supply and demand plans are measured against the organization’s financial considerations.

- Finalize and present the S&OP: The plan is finalized and is ready to present to the organization and shareholders.

Since S&OP is a complicated collaborative process that spans multiple areas of an organization, it can have some challenges. The most common challenges include:

- Creating accurate and reliable reporting on supply and demand to inform company decisions

- Keeping track of and presenting decision criteria in a way that explains impact on KPIs such as supply chain costs, customer service, etc.

- Presenting changes in supply and demand to gain managerial plan approval

- Supply chain planning for introducing new products, phasing out current products or acquiring new products/product lines through merger and acquisition

- Translating large sets of data into information that can be used to make actionable, data-driven decisions

A manufacturer or distributor’s ultimate formula for success is making sure customers have access to items, whenever and wherever they want them. Current logistics and technology capabilities make successful sales and operations planning more attainable than ever before. The question is, at what cost and rate of return?

enVista provides manufacturers and distributors the answers to these questions by helping them attain significant savings, inventory reductions and efficiencies through the optimization of their supply chain networks.

Our sales and operations planning consultants are demand and supply planning experts. We hold suppliers accountable to help our clients create business transformation and drive profits with supply chain and S&OP best practices.

Companies that integrate sales and operations planning (S&OP) into their daily planning and execution are equipped to address order forecast anomalies as well as production and capacity limitations. This places your organization ahead of the competition, even in unfavorable circumstances.

These same companies may not always fulfill 100 percent of the ordered quantity as requested, but they make accurate promises to their customers based upon customer priority, profit margin and supplier capacity, and they strive for continuous improvement.

Our sales and operations planning process will enable your company to:

- Optimize production and inventory costs through supply chain optimization

- Synchronize between departments

- Create supply and demand plans to increase customer satisfaction

- Lower costs by applying the correct resources in order to meet demand

- Develop better accountability and teamwork by decreasing functional boundaries within your organization

Benefits of Working with enVista

Planning as a Service

enVista’s S&OP planning consultants will leverage their deep knowledge and experience in sales and operations planning to help you improve your strategic planning and decision-making our. Our consultants have extensive experience in a range of industries, understand industry best practices and excel at tailoring planning solutions to meet the unique needs and goals of each client. We’ll synchronize supply with demand to meet service and profitability expectations while elevating customer service and holding suppliers accountable.

With the support of our planning experts and advanced analytical tools, businesses can streamline their operations, optimize processes, and enhance accuracy in areas such as demand forecasting, inventory management and resource allocation.

Data-Driven Decision Making

Through deep analytics, we can help you identify trends and performance issues, forecast demand and set future fill rate expectations and labor requirements.

Accountability in Every Step

Our consultants will conduct operational assessments to help your organization identify key performance metrics, create policy documents to guide the process and develop a complete RACI chart.

Unmatched Success

enVista has helped many organizations achieve significant gains in efficiency and customer satisfaction. Our consultants worked with a leading sock and legwear designer and manufacturer to improve its S&OP strategy. By developing a multi-node inventory strategy model, the company benefited from inventory reductions of up to 10 percent and a 33 percent reduction in lost sales.

Let's have a conversation.®

We deliver exceptional solutions. Learn how we can accelerate results for you and your organization.