Your organization has gone through the process of investing in new supply chain execution technology to optimize inventory management and material flow across a multiple-warehouse network. As you evaluated opportunities for quantifiable return on investment for this project, receiving efficiency most likely factored into your savings calculation. Most companies measure improvement in receiving processes in the time it takes to get received product off of an inbound truck. checked-in, and put-away into available inventory; this is often referred to as “dock to stock time.” Best practices define benchmark “dock to stock” timing as less than twenty-four (24) hours with the opportunity for reductions at less than eight (8) hours for companies who invest in warehouse solutions with directed-put-away functionality.

Increase ROI Through Successful Warehouse Slotting

A well-thought-out slotting strategy also enables businesses to minimize wasted space and maximize storage capacity within the warehouse. Increase ROI using the right tools, strategy and management plan with successful warehouse slotting.

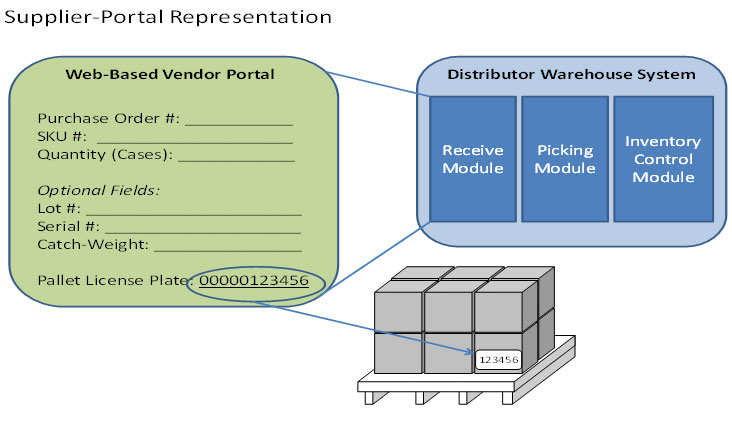

For companies who want to significantly impact the actual product receiving time, they must include process changes with their key suppliers. Distributors who are able to partner with their suppliers to discretely identify the purchase order, item number, quantity, and item characteristics like lot number, serial number, or catch-weight at the pallet level can expect immediate dock-to-stock timing. Unfortunately, most distributors never take advantage of these benefits, nor tighter collaboration with their suppliers because they are mislead that the most common forms of supplier collaboration, advanced shipping notices, are expensive and require a significant information technology investment for the supplier.

A common function offered by most leading supply execution software vendors is a web-based “portal” application that allows both internal and external partners a cost effective option to significantly impact the dock-to-stock time. Most of these “vendor-portal” applications require vendor partners to provide internet access and an optional label-printer in order to support using this application; an investment of less than $2,000 in most cases. In return, the distributor’s supplier can enter advanced shipping notice information directly into the distributor’s warehouse management system automatically formatted and compliant for immediate use by the distributor.

In addition to the supplier-to-distributor information sharing process described above, supplier-portals have been successfully deployed to support the following additional internal and external partner collaboration:

- Warehouse-to-Warehouse Information Sharing – If your organization has multiple warehouse locations, supplier-portals can be used as an interim solution to providing warehouse-to-warehouse transfer information. A shipping warehouse, not using the warehouse management application, can communicate with the receiving warehouse, already supported with a warehouse management system, thru a portal application; thus helping reduce the dock-to-stock time for the receiving warehouse.

- Cross-Dock Location Information Sharing – Within your supply chain, if you use interim locations (cross-dock locations, transfer centers, third-party warehouses) to move product inbound or outbound, portal technology can provide inventory visibility and tracking at remote locations. This information can provide a distributor real-time status on product coming inbound while it exchanges carriers as well as providing customers real-time updates on the status of their orders.

- Customer Store Inventory Management – Distributors that support replenishment order fulfillment with their customers (e.g. store level inventory) but who have not integrated with point-of-sale technology to understand real=time buying can use a portal application to manually record order requirements. Likewise, customer stores can record inventory received at their store directly into a portal application configured to support each store as a logical warehouse or location entity.

In summary, web-based portal applications provided by supply chain execution software vendors can support cost savings opportunities for the distributor by allowing internal and external trading partners a cost-effective method to record advanced shipping notice transactions. Likewise, these same portal applications can provide real-time information to a distributor’s supply chain even when product is physically handled and tracked at remote locations.