A common adage in the manufacturing and retail world is, ‘inventory is a necessary evil’. While businesses need to carry enough inventory to fulfill customer orders, carrying too much of it only increases the inventory carrying costs. Thus, maintaining an adequate amount of inventory and having good inventory visibility is key to organizational success. Managing inventory can be one of the most difficult parts of running a business. For retailers, inventory is typically spread across various distribution centers (DCs) (central and regional) and stores, and keeping an account of inventory at all these locations can quickly become challenging. Further, if the retailer also does ecommerce, then inventory plays an even more critical role because they need to consider order promising based on current inventory levels.

In a pure-play retail business, a customer walks into a store, picks up a physical item and purchases it at a cash register. However, in an ecommerce business, the opposite occurs. The customer visits its webstore, purchases the item and then receives the physical product either by via shipping or pickup from a location. In the latter situation, before the business can accept the customer’s order online, it must ensure there is inventory available to fulfill the order. If a business does not have good visibility of inventory, it is very easy to over-sell items that would lead to order cancellations and customer refunds – lowering customer satisfaction and reduced brand image.

An important piece of information such businesses need to have is the available to promise (also called ATP) inventory. This is the inventory that is available for new customer orders and is not yet committed to any existing order.

1. Simplistic Scenario

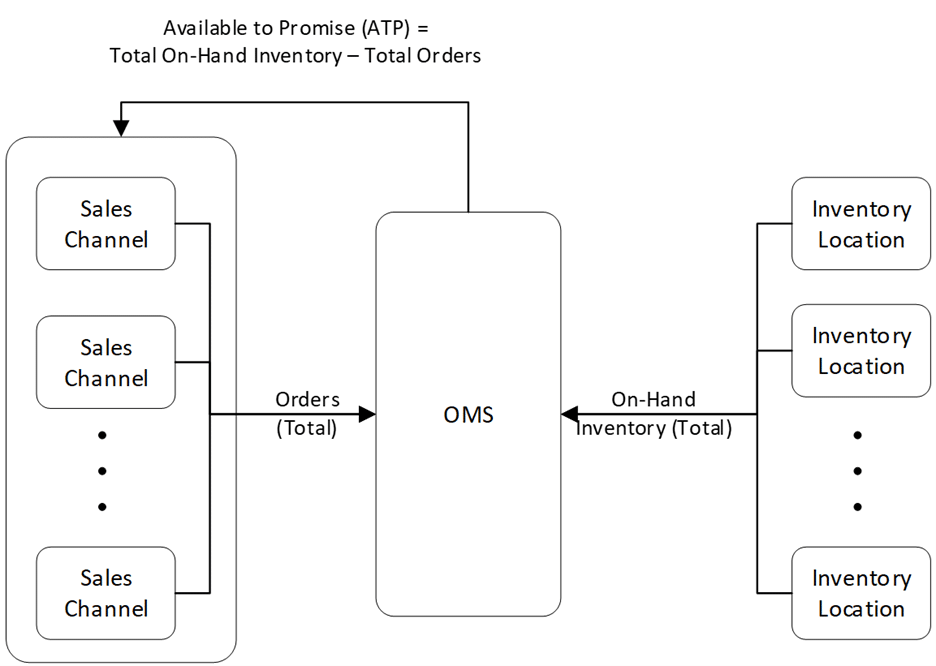

In the most simplistic forms, this equation can be written as:

ATP Inventory = On-Hand Inventory – Orders Already Accepted From Customers

On hand inventory picture is obtained from the inventory locations that the organization maintains. As mentioned earlier, they could be several of them like various DCs, physical stores, etc. We also make assumption here that the inventory locations will also act as fulfillment nodes that will fulfill the customer order. Further, the orders that are already accepted from customers is available from the platforms that accept customer orders (also referred as sales channels). Again, a typical ecommerce organization can configure several sales channels such as U.S. webstore, Canada webstore, B2B site, employee rewards program site, etc.

ATP inventory needs to be sent back to these sales channels so that they can use this number to determine if they can accept new customer orders or not.

The diagram below illustrates the scenario mentioned above:

Since all these values constantly change with time, the latest ATP inventory needs to be constantly fed. A good order management software needs to be efficient to perform this activity constantly and without much processing delay.

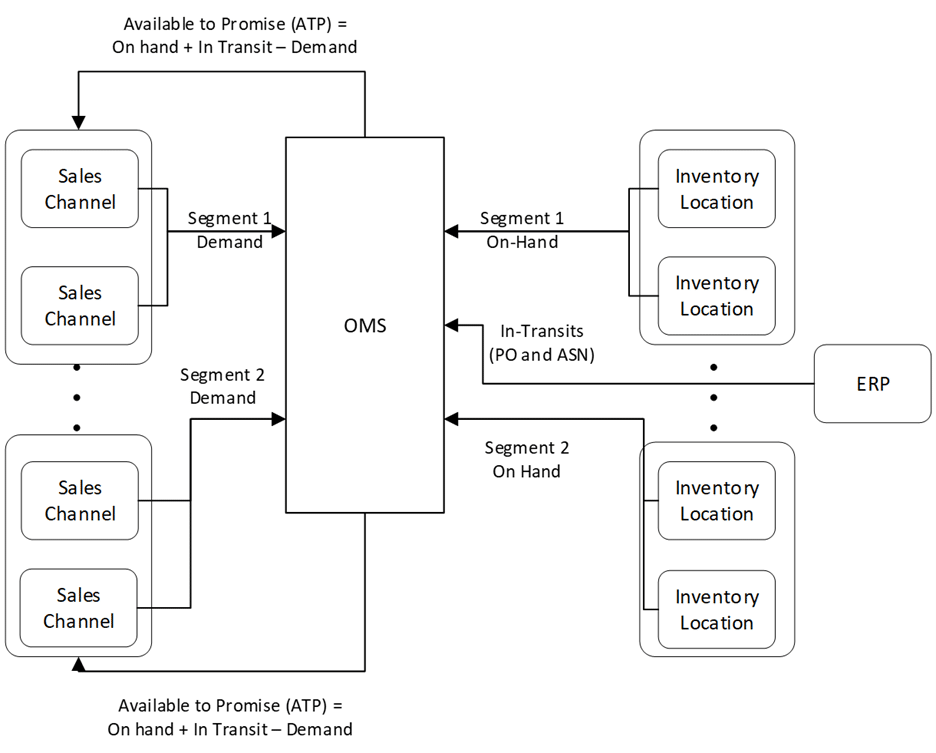

2. Incorporating segmentation and in-transit inventory

Things rarely remain simple with ecommerce businesses, especially when they are global in nature. The business could set up specific inventory locations to fulfill orders from specific sales channels. An example could be U.S. DCs fulfilling only U.S. orders and China DCs fulfilling rest of the world orders. Hence, we can create market segments that maintains relationship between sales channels and inventory locations.

12 Dirty Little Secrets Retailers and Manufacturers Need to Know About Inventory Optimization

Get the low-down on the secrets retailers and manufacturers need to know about inventory optimization.

Further, the businesses might want to accept customer orders based on inventory that is not on hand in the moment but is in-transit and soon to arrive. Typically, purchase order data and advanced ship notices from vendors can provide visibility of incoming inventory. Such data is usually available in the organization’s enterprise resource planning (ERP) system. ERP system can be integrated with the OMS system to get visibility of in-transit inventory. This data can also be incorporated into ATP calculation.

A more advanced equation for ATP calculation is as follows:

ATP Inventory (for a segment) = On-Hand Inventory (for the segment) + In-Transit Inventory (for the segment) – Orders Already Accepted From Customers (for the segment)

We can depict this equation in the following diagram:

In both the above scenarios, we notice that the order management system plays the most important role in compiling all the needed data and feeding to the right system to stay on top of inventory picture. Overall, choosing a robust and efficient OMS solution is the key to avoiding most of the inventory optimization and visibility problems.

About The Author

With over 25 years of IT experience, Manu Satsangi is a Senior Solutions Architect at enVista. Satsangi brings leadership experience in architecting solutions, pre-sales and project delivery in ecommerce, packaged solutions & ERP implementation, M&A and divestiture IT integration.