One of my close business colleagues gave me a book to read called, Vested Outsourcing by Kate Vitasek. He had recently attended the ARC Forum where Kate spoke about concepts from her book, including the “Five Rules that will Transform Outsourcing.” The book was interesting and an easy read.

I was intrigued by Vitasek’s writing, and as it turns out, I fully support her message and the book’s overall premise. Vested Outsourcing explores the concept of moving beyond what I refer to as “Type I partnerships,” whereby a contract between a supplier and customer is based squarely on price and activity. Vitasek rightly stresses the value and important of moving instead to “vested outsourcing.” However, I would argue that “Vested Partnership” is a actually a better term than Outsourcing for several reasons, but primarily because the end goal in any business partner relationship is to create a partnership based upon transparency, collaboration and improved cost containment or reduction whereby all parties have a “vested interest” in the outcome.

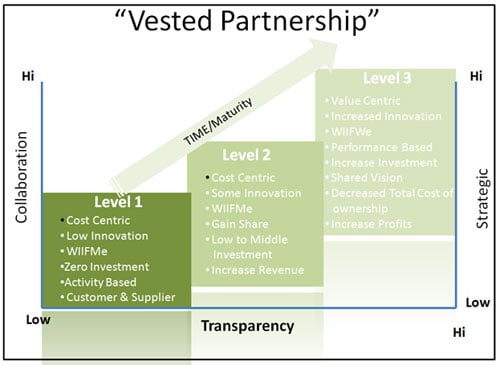

A “Vested Partnership” seems like common sense. I challenge the fact that a “Vested Partnership” is an evolutionary vs. revolutionary process. However, common sense many times is lost on personal agendas and policy constraints within an organization. The end game, which is what I call a Type III partnership, takes time, commitment and openness to think differently about solving hard and complex supply chain problems. But before you can move to a Type III partnership you must progress you’re your way through what I refer to as Type I & II partnership (reference illustration 1).

Unfortunately in today’s supply chain arena there are few, if any, companies that are really effectively managing their extended supply chain from source to consumption. In my 20 years of experience in manufacturing, distribution, transportation and supporting supply chain technology, I have not seen a wholly synchronized supply chain from source to consumption. This includes, DELL, GE, and yes even Toyota.

I do want to congratulate Vitasek and her contributing authors, because the book does provoke conversation and is on point regarding the value Vested Partnerships could bring. I use the word conversation vs. dialogue, because the distinction between the word choices is that conversation is free of bias and “right and wrong” objectives. I have had a number of conversations within our internal team and with clients regarding the concept. Is it a new concept? The answer is “NO,” Japanese car manufacturers have used vested partnership agreements to drive waste out of manufacturing for 40 plus years, and over the last 10 years the same mindset has applied to their distribution network to service their dealers.

Increase ROI Through Successful Warehouse Slotting

A well-thought-out slotting strategy also enables businesses to minimize wasted space and maximize storage capacity within the warehouse. Increase ROI using the right tools, strategy and management plan with successful warehouse slotting.

For 3rd Party Logistics Services providers (3PLs), this book should be a wake up call. I know of at least two large 3PLs that are on global road shows discussing the concept of Vested Partnership with their clients and prospects. Why? Because the fundamental principle behind vested partnership is to move to a Type III level that requires a new mindset: What is in it for WE, not ME.

As for traditional invoice audit and payment companies, that charge clients based on transaction cost alone , this book delivers a rude awakening. The value they add is minimal, since they are not incented to proactively add value. I would argue that invoice audit, payment and GL account coding providers should provide yearly, if not quarterly, rebates back to their customers. Why? Because as a customer transactions increase, the audit company’s cost decreases. In addition, traditional invoice audit and payment companies are not improving the value stream of their customers’ supply chains. Granted, they are eliminating Muda (Waste) by standardizing processes, but beyond the first year’s savings, how are they adding value? The traditional activity-based costing method is a means of the past.

A Level III partnership is focused on value and the way two or more companies can improve the value stream of services or products that are being delivered by the supplier(s). If you are supplier that provides a service or an actual product, I would like to think you are asking yourself, How can WE add value through information, data, and innovative technology?

Level III partnerships must start with a shared vision and ask the hard question, What do you want more of? For most companies, it is increased profitability and Net Operating Income (NOI). Type I and II partnerships are cost-centric models focused on, “I have something that I want you to do for me, give it to me at the lowest total cost, or else.” This makes it difficult for any supplier to become innovative, creative or motivated to invest in new technology, resources or process improvement. Matter of fact, it encourages the opposite. If the customer is dysfunctional, then the supplier wins and takes advantage of the customer by developing new activities that may or may not be adding value in the supply chain.

Can you achieve a Type III Vested Partnership? The answer is yes. We at enVista have proven the concept and have developed a methodology to get any company there. In fact, we actually implemented these practices within one of our own business units (enVista Freight Management) in a proof of concept test with a very large e-commerce retailer. We are a supply chain consulting firm that has a unique twist; we actually run numerous transportation operations for clients. What a concept to actually execute what you consult! It is difficult to be a trusted advisor to a client but never execute on or implement the very practices you preach. Therefore, we walked our client through our Vested Partnership model and asked the client, What type of partnership do you want? We were expecting them to say somewhere between Level I and Level II, but to our surprise, they wanted a Level III partnership from the start. We openly discussed the pros and cons of each partnership level and they were adamant they wanted a Level III vested partnership.

The collective group challenged traditional thinking by first determining what both companies really wanted more of and what and how a picture of success should be defined. More importantly, both companies also considered how to correct behavior if both companies were not moving in the right direction and achieving the common goals and objectives. If you do not take away anything else from this blog, take away this!! Level III Partnerships require a recovery system to be effective. Life and business are not always perfect, and when two parties are involved, there will always be times when someone drops the ball or actual execution gets out of alignment with outlined goals.

You may note that I just contradicted myself because Level III partnerships need to evolve and mature over time. You are right, they do. The Level III example that I gave above is very rare. The only way it worked is because both organizations, enVista and a big mass e-commerce retail client, were willing to have an honest and open conversation. (Not to mention the leaders from both organizations are change agents and out-of-the-box thinkers). Starting at Level III is rare, but not impossible.

In summary, I want to thank Kate Vitasek for inspiring me. Her book has validated the importance of Vested Partnerships, the same type of partnership enVista has been consulting on and putting into practice with its own clients for the last eight years.