In my last post, I wrote about why network design projects require a consolidated and cross-functional team effort that includes inventory optimization or simulation. I really want to emphasize the importance of inventory optimization. It is hard to believe, but Microsoft Excel is by far the most used tool for planning and forecasting inventory. Yes Excel! Why? Because it is simple to use, it is has an intuitive interface, it has been in place since the 80’s, and more importantly, it is extremely inexpensive.

Believe it or not, we have multi-billion dollar retailer clients that plan and forecast inventory in Microsoft Excel. However, Excel reaches an inflection point where it will not suffice to plan a forecast inventory for single or omni-channel companies. I don’t want to completely dismiss Microsoft Excel because over my 25-year career I have seen that Excel does a great job in certain industries and for certain products that are predictable. Where it falls short is in instances where the supply chain is complex and variability is high. A good example would be a retailer that buys product from LCCs and has more than one channel to fulfill.

12 Dirty Little Secrets Retailers and Manufacturers Need to Know About Inventory Optimization

Get the low-down on the secrets retailers and manufacturers need to know about inventory optimization.

There are great planning, forecasting and replenishment solutions on the market. It is important to separate merchandise planning from inventory optimization, or what I refer to as execution. Planning can be characterized as a top-down planning (category, department, class or sub-class) and assortment vs. execution, which is characterized by demand forecasting, location allocation (stores) and replenishment for single or multi-echelon networks. It seems there is a lot of confusion in the marketplace as to which solution does what. This is partially the fault of software providers not offering complementary suites that handle both planning and execution, and not utilizing one system architecture and platform. Hence, you may be running JDA’s E3 Solution or the old SLIM product and you complete planning using Microsoft Excel. Or visa-versa, you are utilizing SAS’s Market Max for planning and forecasting for new items or fashionable items, but your replenishment team is using Excel to figure how to allocate product by channel.

My point is this – for an omni-channel company to maximize profits while optimizing inventory, you need both planning and execution. Second, you need to evaluate your planning and inventory metrics. If you can eliminate Open to Buy (OTB) then do it, or at minimum combine OTB with other key retail metrics to hold your planners and buyers accountable. The obvious metrics are inventory turns, SKU Behavior, in-stock percentage and forecasting accuracy. Less obvious, but still important are inventory turnover and sales stock ratio, which are great measure of how you are managing your working capital while improving service to your stores (see below).

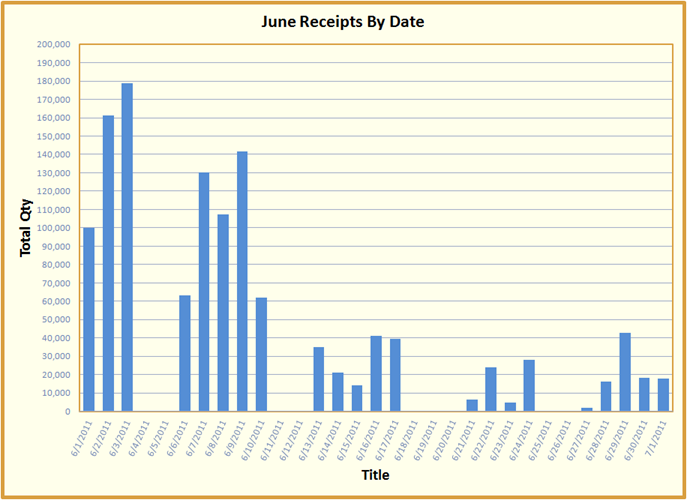

I am not a big fan of a monthly OTB: 1) it increases inventory levels, 2) it can impact forecasting accuracy, and 3) it creates lumpy flow through the supply chain. If there are policy constraints within your organization regarding OTB, then change the metric to a bi-weekly OTB measurement.

I consider inventory sitting in a DC or Warehouse as WIP (Work in Process) inventory. I started my career in manufacturing and WIP was an “evil” word. For that matter, extra inventory is considered waste by LEAN experts. The graph below is a great example of how monthly OTB in a DC has a negative impact on DC operations and storage capacity within the DC. Your collective goal is to determine how to flow inventory through the supply chain while eliminating variability and waste. You may be thinking, “But hey, I buy from LCCs, our lead times are long, we heavily promote our merchandise and there is no way we can flow our inventory.” enVista has a client (a large shoe retailer) that turns its DC inventory 42 times a year. How? They don’t think like a retailer, they think like a manufacturer and they plan their supply chain as if it were long manufacturing process. As a matter a fact, they call their DC personnel “production planners,” not “DC operators.” They have a production plan that starts when a container of shoes leaves the POO.

In summary, thinking, planning and execution are not isolated events. It is continuous flow, not batch and implement metrics that drives the correct behavior. Bad metrics create bad behaviors.